Search Axens.net

C₄ Upgrading

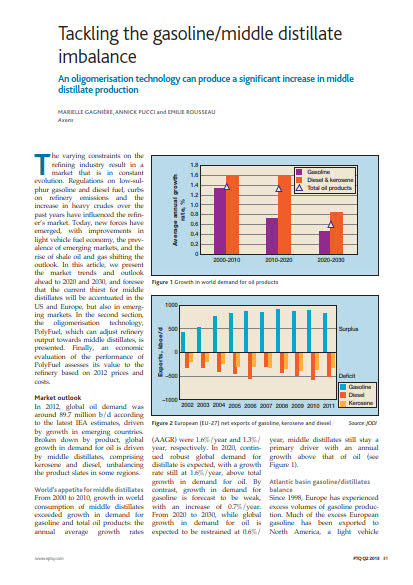

Technical Article - Tackling the Gasoline / Middle Distillate Imbalance

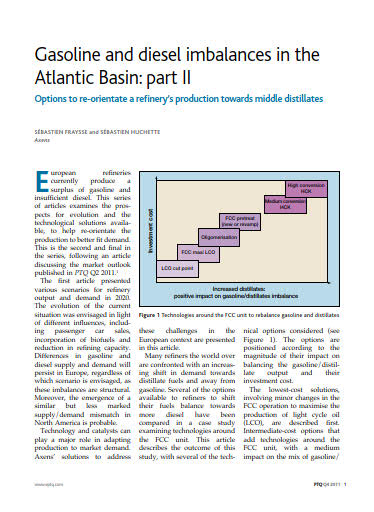

Technical Article - Technical Article - Gasoline and Diesel Imbalances in The Atlantic Basin Part 2

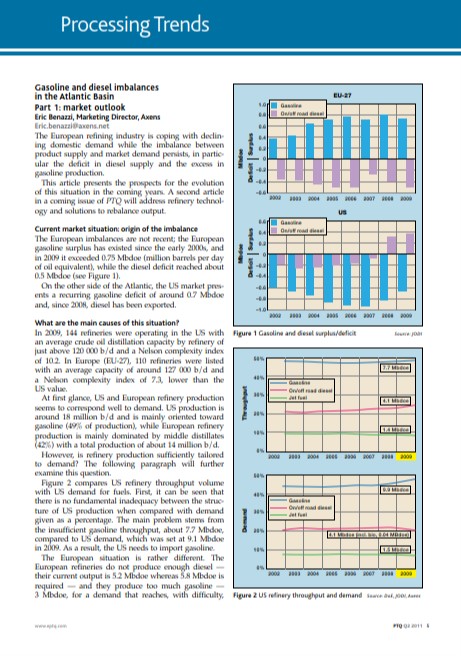

Technical Article - Gasoline and Diesel Imbalances in The Atlantic Basin Part 1: Market Outlook

Commercial Bulletin - Polynaphtha™ & Selectopol™

Commercial Bulletin - Polynaphtha™ & Selectopol™

Conference

San Francisco - UTC-7

3 days

Speakers

David Schwalje

Emerging Market Development Axens Americas

ABLC 2021

Advanced Bioeconomy Leadership Conference (ABLC) is a connected series of 6 conferences and 16 events in total on the most important issues in the Bioeconomy right now. The topic of the conferences ranges from advanced biofuels, renewable chemicals, advanced agriculture, advanced nutrition, sustainable aviation fuels, and advanced biogas.

Carbon Capture, Utilization & Storage

Petrochemicals

Plastic Recycling

Renewable Fuels & Bio-Based Chemicals

Bio Aromatics

Bio Olefins

Bio Ethylene

Bio Butadiene

C₄ Upgrading

Cellulosic Ethanol

Oligomerization

Renewable Diesel and Jet

Lipid Feedstock

Lignocellulosic Biomass

Process Technologies

Drying Series Adsorbent

Mercury Removal Adsorbent

Sulfur Removal for Oil, Gas & Petrochemicals Adsorbent

Americas

+18

Conference

New Orleans - GMT-5

2 days

American Fuel & Petrochemical Manufacturers (AFPM) Summit

The Summit: Excellence in Plant Performance blends AFPM’s traditional refining and petrochemical manufacturing technical curriculum with new creative opportunities that drive excellence in plant performance. Topics and themes throughout the conference will highlight emerging process technologies, process safety, improved reliability and operations, mechanical integrity, training, leadership, and culture.

Petrochemicals

Renewable Fuels & Bio-Based Chemicals

Aromatics Extraction

Extractive Distillation

Liquid Liquid Extraction (LLE)

Benzene Hydrogenation

Benzene Production

Bio Aromatics

Bio Olefins

Bio Ethylene

Bio Butadiene

C₄ Fractionation

Butene-1 recovery

Isobutene Recovery

C₄ Isomerization / Alkylation / Olefins Hydrogenation

C₄ Isomerization

Fluoridric Acid Alkylation

Sulfuric Acid Alkylation

Feed Purification

Solvent hydrogenation

C₄ Upgrading

C₅ Skeletal Isomerization

C₅-C₆ Isomerization

Once-through

Octane Enhancement

Advanced Recycle

Catalytic Cracking

VGO FCC

Resid FCC

High Propylene FCC

Catalytic Reforming

CCR Reforming

Cyclic Reforming

Semi-reg Reforming

Catalytic Reforming

CDU (Crude Distillation Unit)

Cellulosic Ethanol

CO₂ Capture

CO₂ Gas Drying

Cyclohexane Production

Diesel Hydrotreating

EDC Cracking

Etherification

FCC Naphtha Hydrotreating

FCC Naphtha Sweetening

Gas Dehydration & Purification

Solvent Processes

Dew Pointing

Adsorbents

Gas Sweetening

Solvent Based Processes

Cryogenic Processes

Catalytic Processes

Adsorbents

High-conversion Hydrocracking

Kerosene Sweetening / Hydrotreating

Sweetening

Hydrotreating

LNG

LPG Sweetening & Olefins Recovery

LPG Sweetening

Olefins Recovery

Lube Plant

Hydrorefining

Lubes Hydrofinishing

Hydroisomerization & Hydrofinishing

White oils Hydrotreating

Wax Hydrotreating

MEG Recovery

Naphtha Treatment

NGL & Condensates Sweetening

NGL Recovery & Treatment

Olefins Purification

Phenol Production

Oligomerization

Olefins Purification

Ethylene Purification

Comonomer Purification

Propylene Purification

Olefins Removal

Olefins Selective Hydrogenation

C₂ Selective Hydrogenation

C₃, C₄, C₅ Selective Hydrogenation

C₅+ Pygas Hydrogenation

Oligomerization

Heterogeneous Oligomerization

Homogeneous Oligomerization

Oligomerization

Ethylene

Butene

Paraxylene Purification & Production

Phenol Production

Renewable Diesel and Jet

Americas

+93