Unit Monitoring & Performance Management

High-speed data networks, cloud-based systems and advanced data techniques are leading a distinct change in the way industries monitor and optimize operating assets. Refineries that adopt real-time unit monitoring tools incorporating on-demand, advanced modelling of process performance see an immediate marketplace advantage.

Connect’In®

Drive asset performance to optimum with your proactive digital advisor.

Connect’In® is a digital service that improve unit monitoring with the objective to support process and operation engineers and managers in their decisions process. The system is implemented to avoid sub-optimal operation and economic losses due to loss of time.

Key advantages:

- Performance management tool tailored to process unit easy to use that provide a platform for agile & collaborative optimization tasks

- Proactive troubleshooting and alerting avoiding performance losses

- Direct use of licensor high fidelity models

Advanced Process Control

Capturing more value from your process unit through licensor unique approach to APC

APC

Fast paybacks from Axens' Multivariable predictive Control solution using unique process control strategies and proprietary inferential models.

APC provided by Axens ensures robust control, increases process operation stability and allows operators to reach the economical optimum yield through unique services and applications.

Clients’ plants can perform better and more safely with APC by:

- extending catalyst performance and service life

- reducing utility and logistics costs

- saving energy and decreasing carbon dioxide emissions

- avoiding the problems caused by off-specification products

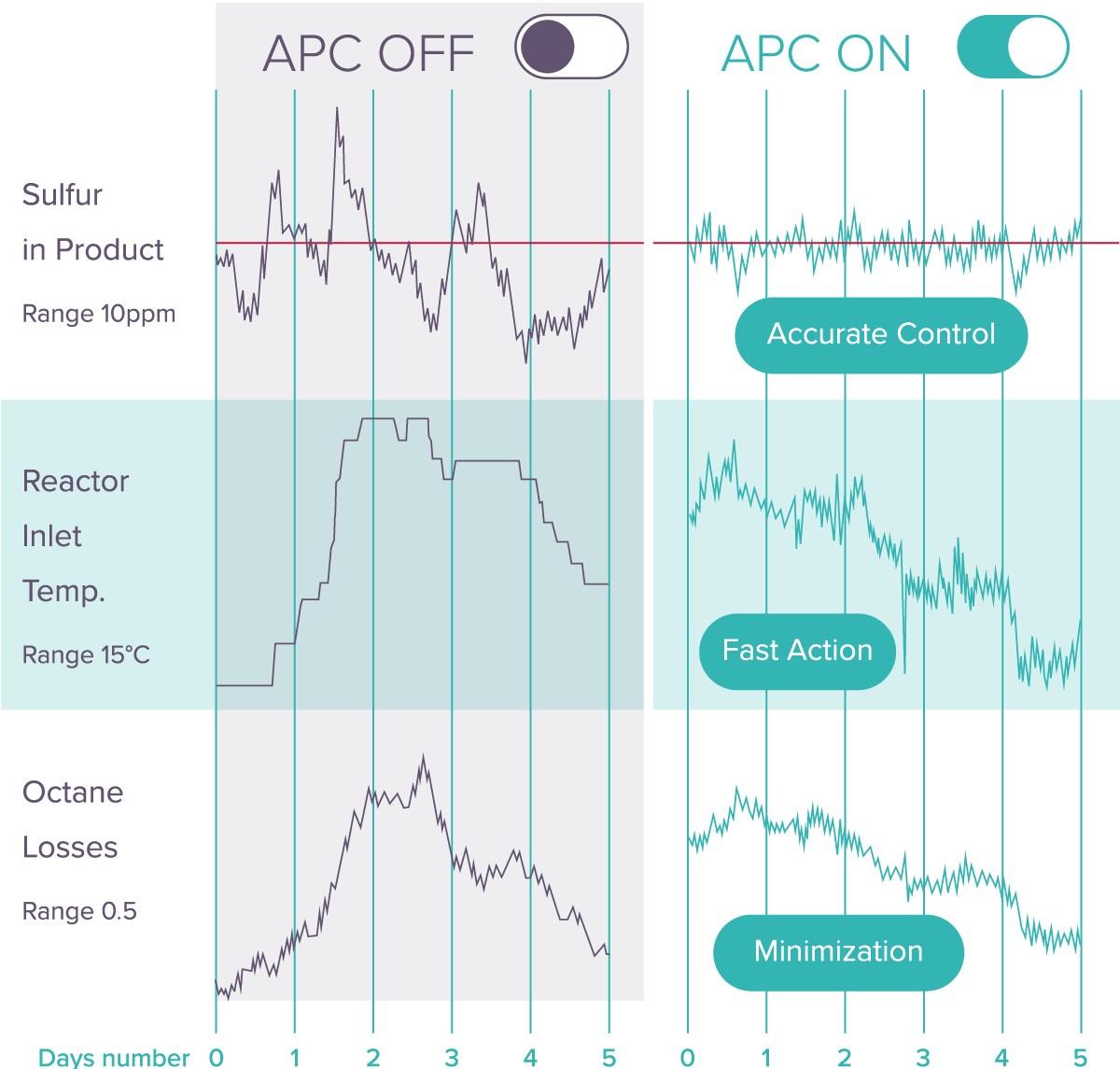

Benefits of APC generated by sulfur control in a gasoline hydrotreater.

Example of 5 days data on Prime-G+ unit: APC keeps the Sulfur of the product at target and minimizes Octane Loss estimated on-line by Axens Horizon inferential.

Key advantages:

- Embedding licensor unique reaction model coupled with an optimizer that will continuously send the best operating targets in order to achieve the greatest yields while taking care of products specification.

- Tailored approach for implementation in collaboration with your APC team

- Axens support over all process unit lifecycle to ensure that APC benefits will be sustained

Operator Training Simulators

A unique OTS solution that provides benefits over the complete unit lifecycle

Operator Training Simulator (OTS)

Enhance Employee Skills Through Accurate and Interactive Unit Simulation powered by Corys state of the art IndissPlus dynamic simulator and Axens high fidely models OTS are a next generation educational tool that helps facilitate safe, efficient, and reliable operations via real-time, dynamic replications of process unit performance in a controlled training environment. The system is designed utilizing proven scenarios - both planned and emergency-based - to maximize operator knowledge retention.

Key advantages:

- A solution fully interoperable with your control system

- Provides operations staff with the opportunity to understand the process significantly prior start up by practicing control scenarios developed by process licensor,

- Provides a platform for the development of Process optimization that later can be interfaced to Axens performance remote monitoring tool, called Connect’In™

Static Operations Simulators

Using Axens high fidelity models

Web-based Process Operations Simulators (WebPOS™)

WebPOS™ are packaged modeling applications that are fine-tuned and approved for refining or petrochemical units. The applications are used by process and planning engineers to meet specific operational needs.

Axens’ approach is to support refinery engineers in achieving operational excellence and maximizing return on assets while optimizing their efforts. An easy-to-use interface coupled with Axens’ expertise in process technology, catalysts and refineries enables operators to maximize their returns from the webPOS™ investment.

For a client already using Axens Connect’In, users will be able to benefit from a unique functionality tuning WebPOS to real process conditions. This is a key building block toward a digital twin of your process unit.

Key advantages:

- A unique what if tool to identify operational changes that positivly impact performance/margin

- Easy of use with no sofware application to install &/or maintain

- A solution to accuratly update Linear Programming planning model of your plant

Fired Heaters & Steam Methane Reformers Rating Software

PFR Engineering Systems, an independently operated Petro-Chem Development subsidiary, provides industry leading softwares for Fired Heater and Furnace rating, widely used in the industry by EPCs and Fired Heater designers. Their offer also include services, training and support.

General Purpose Heater Simulation program (FRNC-5PC)

FRNC-5PC is a rating program for general purpose fired heaters. It simulates most heater types, coil configurations, tube and fin types, and external transfer lines. It can simulate the heat recovery sections of all types of furnaces, boilers and turbines. It also has a user friendly graphical input system.

Key advantages:

- World foremost computer program for fired heater analysis and design

- Detailed and accurate results

- Tool dedicated to End Users (Refiners), EPC companies, Furnace suppliers

Steam Methane Reformer Simulation Program (REFORM-3PC)

REFORM-3PC is a rating program for the firebox sections of Steam Methane Reformers, which are used in Hydrogen, Ammonia and Oxo-Alcohol production. It simulates most reforming furnace types such as Up, Down, or Side Fired rectangular and cylindrical types, as well as Terrace Wall.

Key advantages:

- Furnace Rating and Optimization

- Extend Tubes life

- Check or compare Furnace Designs

Resources

White Paper - Connect’In®: Refinery Data Management & Advanced Analytics and Monitoring Platform

What areas of expertise are needed to mitigate constraints in plant/facility staffing levels?

Video - Energy Efficiency, SAF, Connect'In®, Decarbonization: Transition to Low Carbon Fuels

Any experiences you can share regarding the implementation of carbon management/digital data tools?

What are Tomorrow Megatrends & What is at Stake?

Connected Services Maximize Value Creation of Catalytic Units in MOL Group Danube Refinery

Address Crucial Units’ Operational Challenges & Effectively Minimize Financial Risks With Connect’In™

Rising Petrochemicals

Case Study - The Implementation Of An APC Led To A 12% Decrease Of Octane Loss Resulting In More Than 5 MM US$/year Of Additional Benefits

Read moreWhite Paper - Connect’In®: Refinery Data Management & Advanced Analytics and Monitoring Platform

Technical Article - Petrochemical Complex Digitalisation for Greater Efficiency and Emissions Reduction

Technical Article - Maximize Refinery Profitability with Novel RFCC Technologies

Technical Article - The Digital Process Unit

Technical Article - Good Practice in PYGAS Hydrogenation Operations Through Advanced Process Control

What areas of expertise are needed to mitigate constraints in plant/facility staffing levels?

Any experiences you can share regarding the implementation of carbon management/digital data tools?

What do you see necessary for successful implementation of plant-wide AI and machine learning (ML) in the refinery and petrochemical complex? Can AI/ML strategies provide additional benefits beyond APC?

MiRO & Axens Celebrate Twenty Years of Close Partnership Around Prime-G+® Technology

Axens’ Connect’In® Offer for Biomethane Producers via its Partner Arol Energy

Successful operation of Axens’ units and digitalization at the ERC refinery

Axens’ recent Successes in Hydrocracking

Video - Energy Efficiency, SAF, Connect'In®, Decarbonization: Transition to Low Carbon Fuels

Read moreGet in Touch with Us!

Have questions about our offers and solutions or need assistance? The Axens team is here to help. Just a message away!