Axens provides comprehensive energy efficiency surveys for refineries and petrochemical sites, reducing costs and emissions while improving margins.

Our methodology includes site energy analysis, process benchmarking, and equipment performance review. Specializing in furnaces and heat integration using Pinch analysis, we ensure rapid payback times of 3 to -5 years. A recent case study identified a 15.3% energy reduction with low CAPEX solutions.

At Axens, we provide tailored solutions to enhance your unit's energy efficiency by addressing its unique characteristics and needs. Our approach is built on three key pillars:

Catalyst and process optimization, where we utilize the latest generation of high-selectivity, high-activity catalysts to optimize operating parameters; process and equipment enhancements, leveraging cutting-edge technologies to improve performance; and digitalization and operation, using in-house systems to analyze data, identify deviations, and ensure optimal efficiency.

Fired heaters are significant energy consumers in refineries and petrochemical sites. Enhancing their efficiency can substantially reduce energy consumption. Axens, leveraging the expertise of Heurtey Petrochem Solutions, offers comprehensive services ranging from feasibility and assessment studies to the implementation of optimal solutions for existing fired heaters. Our multidisciplinary approach, encompassing process, thermal, and mechanical expertise, ensures the best outcomes. Additionally, through Nectis, our joint venture with ZPJE, we provide high-efficiency Spiral Tube Heat Exchangers (STHE) to maximize heat recovery.

Multi-Sites Energy Efficiency Audit

Axens was awarded a multisites energy efficiency survey including 2 complex refineries.

With a tailor-made methodology and specific software, Axens successfully carried out this global study giving rise to energy efficiency practical recommendations for the client. After a 7-step study, 74 solutions were identified, out of which 27 were included within the client Action Plan with low payback time.

The solutions proposed lead to a series of improvements: better thermal integration in the units, reduced steam losses, increased furnace and boiler efficiencies, and optimization of the operating.

Quick wins had a potential for saving of around 15% of total energy consumption resulting in more than 40 million US dollars savings per year.

Contributing to Reaching Net Zero Emissions by 2050

A European refiner had a strategic objective to reduce its carbon footprint by performing energy savings on the site heaters and heat exchangers, and at the same time solving their recurrent operating issues in their unit and securing optimal operation from turndown to design capacity.

Using our holistic approach for revamps, Axens helped this operator respond to their emerging needs while achieving energy efficiency improvement.

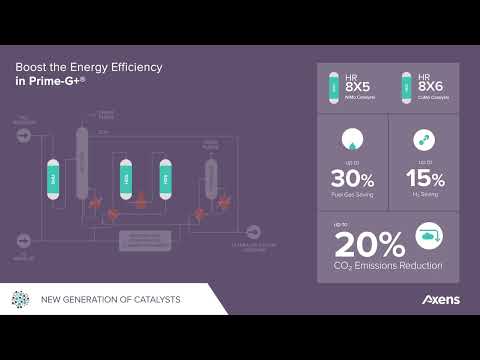

Boost the Energy Efficiency in Prime-G+®

Energy Efficiency Solutions: Axens' Expert Approach

Energy efficiency is crucial for industries aiming to reduce costs and emissions while enhancing operational performance.

However, operators face several challenges in their energy efficiency efforts:

- Economic Viability: Projects must meet strict economic criteria, often requiring short payback periods.

- High Costs: Significant upfront investment required for new technologies and retrofits.

- Aging Infrastructure: Older facilities need substantial upgrades to improve efficiency.

- Technical Challenges: Integrating new technologies with existing systems is complex.

Being a high-efficiency equipment supplier and a technology licensor, Axens is the ideal partner for energy efficiency, providing realistic and well-integrated solutions at the site, unit, and equipment levels to ensure well-predicted and measurable efficiency gains.

Of the solutions identified during energy efficiency survey for a Refining & Petrochemical complex require an investment lower than kUS$ 100.

GHG Emissions effective reduction after a revamping in 2022 of an existing Diesel Hydrotreating unit (>1.5 year Pay Back Time)

Observed gain in efficiency when revamping an existing heater

Documentations

Get in Touch with Us!

Have questions about our offers and solutions or need assistance? The Axens team is here to help. Just a message away!