Air Pollution Control

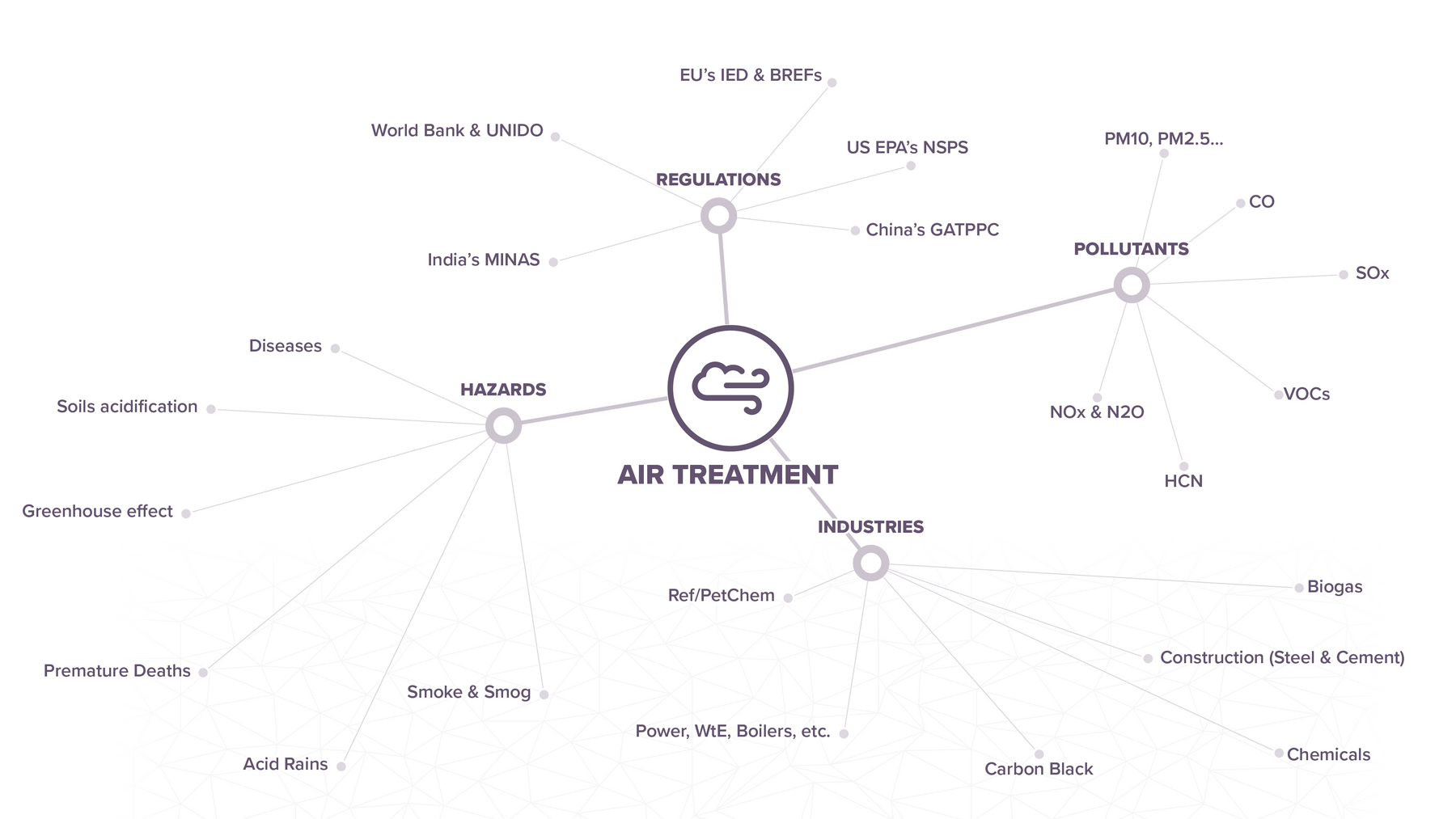

Industrial processes that involve combustion of fossil fuels or materials, like power generation, waste incineration, or construction material production, inevitably produce emissions to the atmosphere containing various pollutants. These emissions include nitrogen oxides (NOx), alongside CO2, which need to be removed before releasing the flue gas or gas purge.

However, eliminating pollutants from industrial gaseous emissions poses challenges. Including costs of implementation and operation, technical feasibility under harsh operating conditions, potential impacts on process performance, plot space availability or even potential trade-offs with other pollutant emissions (such as carbon dioxide or ammonia among others). Moreover, environmental regulations are constantly tightening, requiring technical upgrades.

Air Pollution Control

Reducing pollutant emissions from industrial processes is achievable through various technologies and approaches. However, each approach presents its own challenges, such as cost, technical feasibility and environmental impact. Finding the right balance is crucial to meet environmental targets successfully.

(Image: Furnaces are principal source-points of emissions of pollutants into the atmosphere)

Axens has the capability to accompany various industries in their goal to comply with local regulations and achieve consistently their emissions reduction targets.

With a broad offer in abatement systems (selective reduction, air purification with specialty adsorbents, scrubbing, etc.) coupled with a strong knowledge in heaters and combustion systems, Axens Group has an unique position to understand the stakes of any case.

Implementing tailor-made solutions and utilizing corrosion-resistant exchangers can facilitate retrofits of existing industrial plants to meet environmental targets while enhancing energy efficiency.

(Image: 3D rendering of a thermally integrated SCR DeNOx system for high energy recovery)

The complexity of Air Treatment stakes: selected examples

Nitrogen Oxides Reduction Systems (DeNOx)

Axens expanded its innovative solutions portfolio for industrial flue gas treatment through the acquisition of the Danish Flowvision, specialized in emission abatement systems.

Bespoke Selective Catalytic (SCR) and Non-Catalytic Reduction (SNCR) packages are available with optional treatments of other pollutants, such as CO, HCN, etc.

Flowvision Air Treatment offering

SCR DeNOx - Commercial Bulletin

SNCR DeNOx - Commercial Bulletin

APH + SCR DeNOx - Commercial Bulletin

Air Preheaters (APH)

All the solutions offered for abatement of air pollutants can be integrated with Air Preheaters (gas/gas or gas/liquid heat exchangers) ensuring a deep thermal integration and associated energy recovery. The heat exchange sections will be tailored to the specifics of the process, raw/flue gas composition, site configuration and customer preferences. Additionally, Axens can offer Clear Channel Technology for trouble-free operation, Corrosion-free operation below the Acid Dew Point (ADP).

With Axens

Strong Know-How in Combustion

Knowledge of Various Processes and Industries

Moreover, Axens’ subsidiary Flowvision has been supplying abatement systems throughout the world for industries such as Coal Fired Utility Boilers, CFB Boilers, Biomass Boilers, Waste-to-Energy Plants, HRSG, Engines or Cement Kilns.

Axens Group detains a broad industrial experience, allowing to offer lean and efficient solutions.

Environmental Compliance and Beyond: Coupling with Energy Efficiency

Get in Touch with Us!

Have questions about our offers and solutions or need assistance? The Axens team is here to help. Just a message away!