Alkylate is a superior component that increases the octane of premium motor fuels. ExxonMobil’s proven Sulfuric Acid Alkylation (SAA) technology reacts light olefins with isobutane to form high value alkylate for gasoline blending.

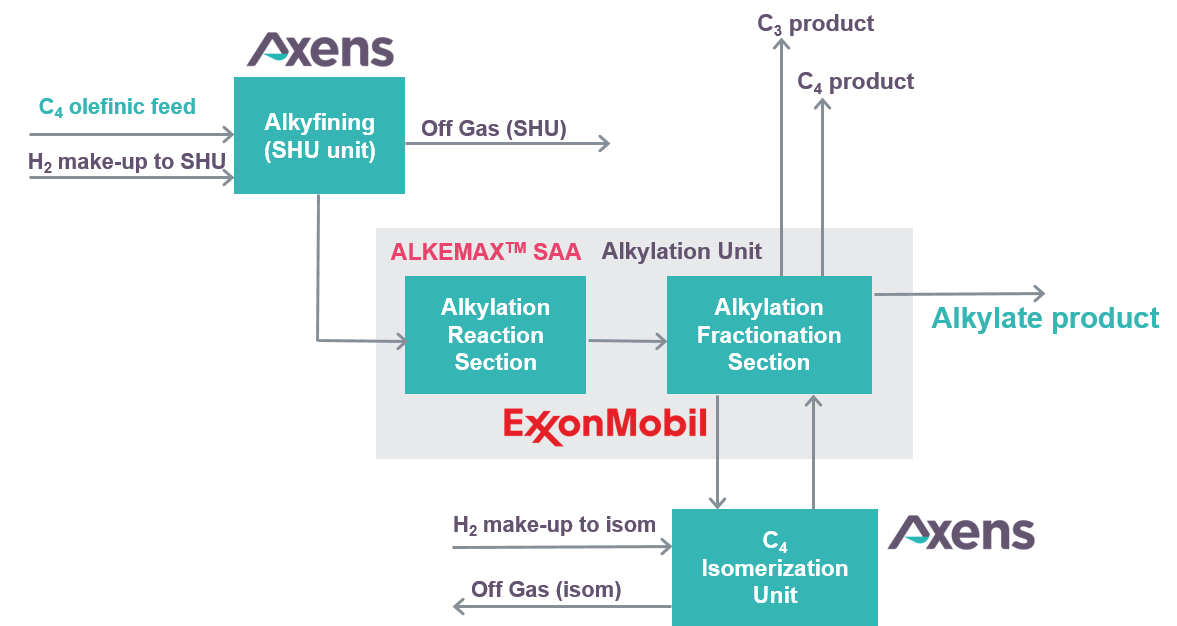

ALKEMAX™ SAA technology is based on ExxonMobil’s 60+ years of design and operational experience, and is used in some of the world’s largest refineries. ExxonMobil and Axens have signed an alliance agreement for the sublicense of ExxonMobil’s Sulfuric Acid Alkylation technology. This alliance leverages collective expertise by providing a streamlined solution and proven technologies to optimize high-octane fuels production.