The Atmospheric and Vacuum Residue (AR/VR) hydrotreater is a key refinery unit which improves Residue Feeds for Fluid Catalytic Cracking (RFCC) units and which produces additional diesel as well as low sulfur fuel oil. Residue hydroDeSulfurization units (RDS) improve downstream conversion operations by eliminating difficult feed components thus enabling the refinery engineers to squeezing the most out of the bottom-of-the-barrel, and maximize profitability.

Axens' unique portfolio for AR/VRDS processing is highlighted by the Hyvahl™ technology and a full range of advanced resid hydrotreating catalysts.

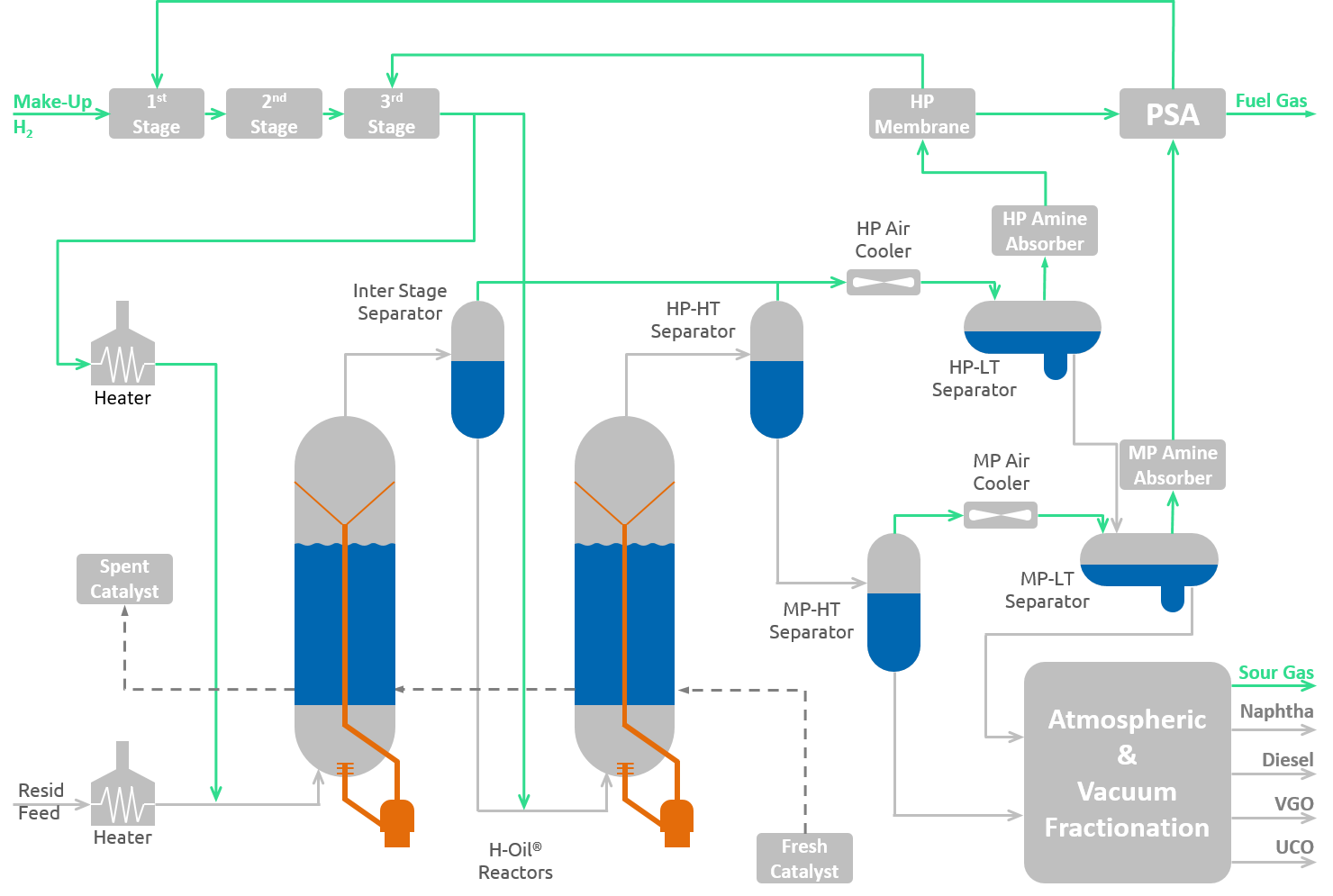

Atmospheric residues (ARs), vacuum residues (VRs), and also refractory oils such as heavy deasphalted oils (DAOs), straight-run vacuum gas oils (VGOs), heavy coker gas oil (HCGO) or coal-derived oils such as coal slurries (Direct Coal Liquefaction, DCL), as well as PyOil from steam crackers are all potential H-Oil® feeds.

Testimonies

Upcoming Events

ME-TECH 2025

Resources

Technical Article - Guiding the crude-to-chemicals complex towards a net-zero future

Maximizing the Production and the Transformation of Aromatics

Targeting the Highly Coveted Olefins

Recommended Process Routes for Maximized Oil Conversion to Aromatics and Olefins

Maximizing the Production and the Transformation of Aromatics

Targeting the Highly Coveted Olefins

Recommended Process Routes for Maximized Oil Conversion to Aromatics and Olefins

From Refining to Chemicals, a Switch of the Yield in 4 Stages

White Paper - Crude-to-Chemicals

Technical Article - Guiding the crude-to-chemicals complex towards a net-zero future

Technical Article - Implementing Advanced Technologies for Crude to Chemicals Projects

Technical Article - Flexible Upgrading of Heavy Feedstocks

Technical Article - First Residue Hydrocracker Starts-Up In Asia/Pacific

Can you recommend a process route for residual fuel oil feed to help comply with the IMO’s revised targets for bunker fuels?

Axens and Sinopec Zhenhai Refinery & Chemicals Company announce the completion of the Performance Guarantee Test Run of H-Oil® unit

Axens Signs an Agreement with Hengyi Industries to Provide FLEXICOKING™ Technology

Axens and ExxonMobil Sign Alliance Agreement

Axens and ExxonMobil Catalysts and Licensing LLC Sign Alliance Agreement

TO CONTACT US

Please fill in the contact form below