Search Axens.net

Process Technologies

process_technologies

Solutions - Advanced Process Licensing Solutions

-

Conference

Amsterdam - CET

3 days

Taking place in Amsterdam from 7 - 9 June, Sustainable Aviation Futures Congress is a high-level, content-rich networking event that will showcase the latest strategies for decarbonisation, key industry challenges and exciting opportunities for airlines, corporate organisations and fuel producers.

Renewable Fuels & Bio-Based Chemicals

Bio Aromatics

Bio Olefins

Cellulosic Ethanol

Renewable Diesel and Jet

Lipid Feedstock

Lignocellulosic Biomass

Bio-Alcohols / Bio-Olefins

Process Technologies

Arsine Removal Adsorbent

Chloride Removal Adsorbent

Drying Series Adsorbent

Mercury Removal Adsorbent

Sulfur Removal for Oil, Gas & Petrochemicals Adsorbent

Europe

+14

Webinar - Axens Solutions to Energy Transition Towards Sustainable Aviation Fuel (SAF)

Commercial Bulletin - Low Carbon Hydrogen Purification

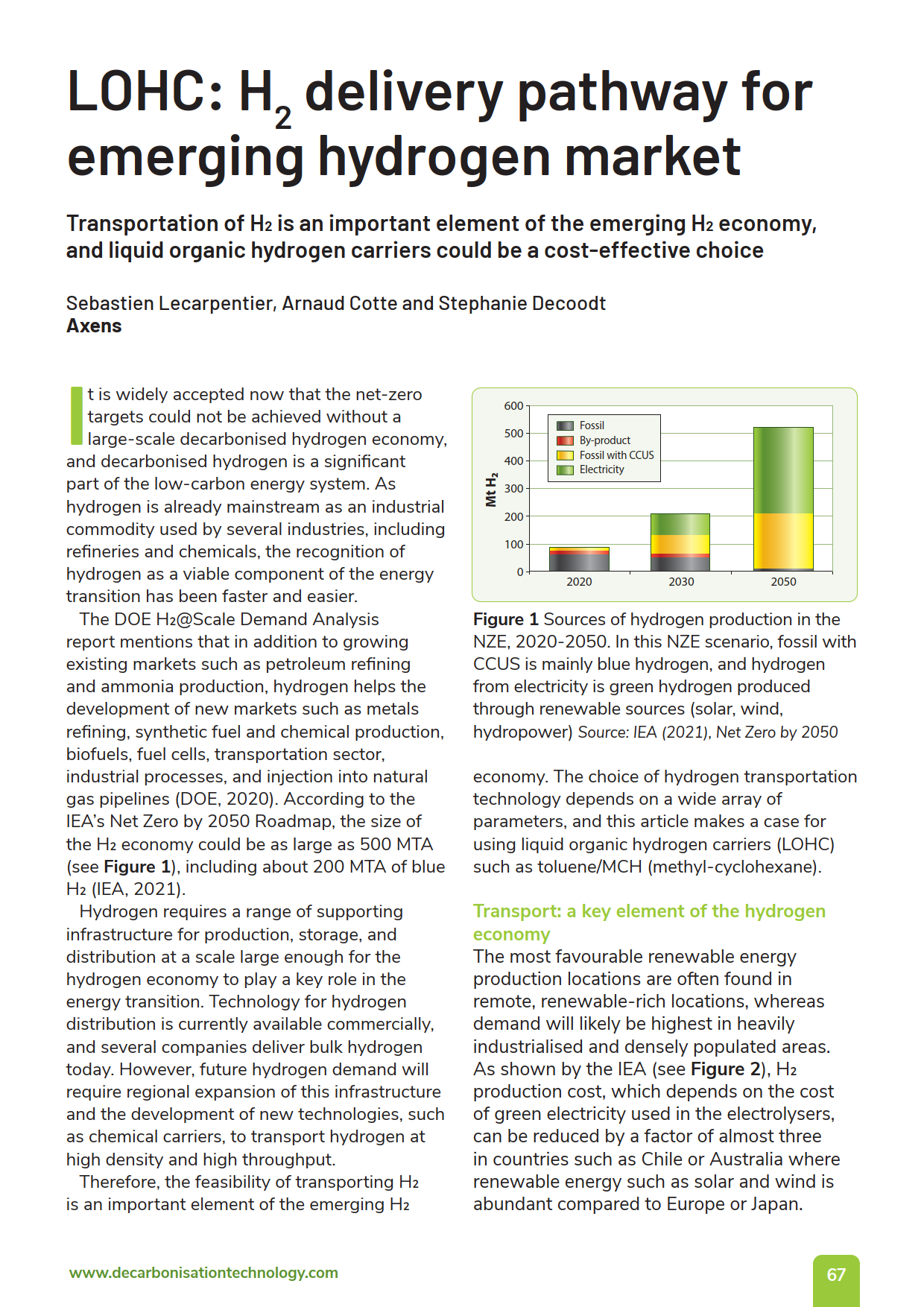

LOHC: Hydrogen Delivery Pathway for Emerging Hydrogen Market - Technical Article

-

Conference

Dubai, UAE - GMT+4

3 Days

Speakers

Vinay Joshi

Regional Product Line Director-Furnaces

Fabien Lundy

EMEA Commercial Vice President

ME-TECH 2023

It is the 13th Middle East Technology Forum for the refining & petrochemical community to address, exchange and identify solutions to the pressing questions and challenges being faced by the Global and Regional downstream sector.

-

Conference

Brussels - GMT+2

2 Days

Speakers

Guillaume Cheviron

Technologist, Renewables Product Line

Biofuels International Conference & Expo

Biofuels International Conference & Expo, held in Brussels, Belgium, will bring together leading producers, suppliers, regulators and other engaged organisations over a two-day period. High-level speakers, and experts in their field, will address a range of topical issues relating to the biofuels sector.