Axens Offer

AdvaSulf™ portfolio provides reliable, flexible and low-cost solutions for Sulfur Recovery to meet the most stringent environmental standards, at minimized capital and operating costs. The portfolio covers a complete range of processes for any applications: gas plants, refineries, upgraders, biogas, shale gas, etc., in a wide range of single train capacities, from a few tons per day to more than 2,200 tons per day of sulfur produced.

When Sulfur Block is required, Axens has the internal knowhow to include in the Process Design Package (PDP) the following additional units: Sour Water Stripper (SWS), Amine Regeneration Unit (ARU) and Acid Gas Enrichment (AGE). In addition, the sulfur block can be completed by developing a duty specification for the sulfur forming unit.

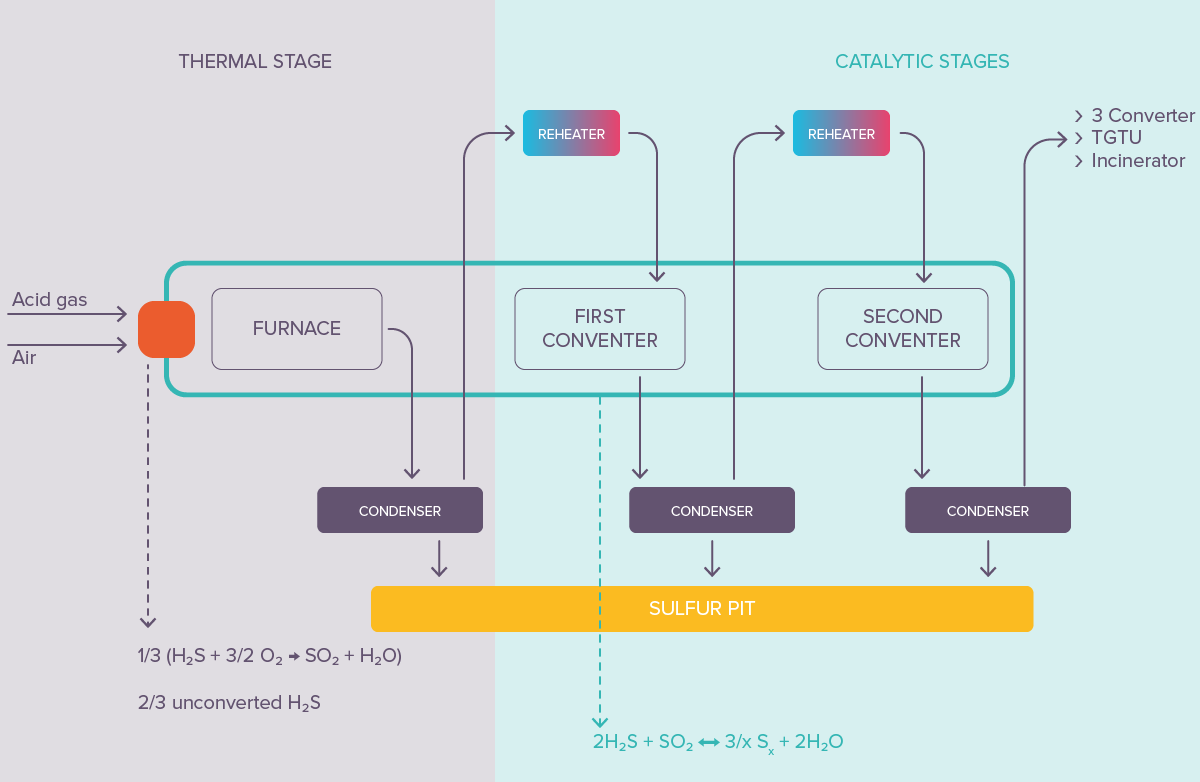

The traditional Claus-based process is composed of two steps, a first thermal stage and a second catalytic stage. In sub-dewpointing Claus, the latter stage differentiates from the conventional Claus process as it has 2 permutable catalytic stages (Hot & Cold reactors), where the second stage works at sub-dewpoint condition.

The Claus and other advanced process solutions for sulfur recovery involve using thermal and catalytic reactions. Sulfur recovery can range from 95% up to 98% depending on the feed and number of reactors used.

Promoting the Claus reaction kinetic while avoiding pore blockage in the catalyst is key to sulfur recovery maximization. Axens aluminas provide first-class performance thanks to their optimized properties. When dealing with residual COS and CS2 species, titanium-based catalysts, used alone or in combination with aluminas, is the solution of choice to reach outstanding performances.

Tail Gas from the Claus section still contains unrecovered sulfur species: H2S and SO2, residual COS and CS2, traces of vapor and liquid elemental sulfur.

To further increase recovery yields, tail gas leaving the Claus section can be treated using different processes. Axens proposes dedicated technologies and products for sub-dewpoint applications or hydrogenation plus amine process (Sultimate™) where sulfur species are reduced back to H2S and recycled to the Claus section inlet. These optimized catalysts help reaching the ever-increasing stringent specification on sulfur emissions.

Upcoming Events

Resources

Video - Axens Sulshine® CRS 41 - Introducing the Newest Addition to the Sulfur Recovery Catalysts Family

Technical Article - New low-density titanium dioxide catalyst for improved sulphur recovery

Case Study - Successful start-up of a Sub-dewpointing Sulfur Removal Technology

Video - Axens SmartSulf®️ Technology - Up to 99.7% Sulfur Recovery without TGTU

Sulfur Recovery, Recommended Route to Meet Environmental Specifications

Case Study - Successful start-up of a Sub-dewpointing Sulfur Removal Technology

Read moreTechnical Article - New low-density titanium dioxide catalyst for improved sulphur recovery

Technical Article - SMARTSULF™ Process In Direct Oxydation Mode For Very Lean Acid Gas Application

Technical Article - Boosting Sulphur Recovery With Sub-Dewpoint Processes

Technical Article - Advantages Of Modular Construction For Small Scale SRU In Harsh Climates

TO CONTACT US

Please fill in the contact form below