The latest generation of boosted catalyst is called Impulse®.

This hydrotreating catalysts range includes HR 1226, HR 1246, HR 1256, HR 1218, HR 1248, HR 1056, HR 1058 and HRK 1448, covering all domains, from naphtha to VGO hydrotreating and hydrocracking pre-treatment.

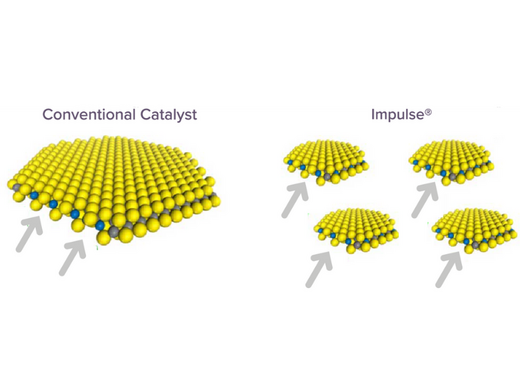

On the left, a schematic representation of the dispersion phenomenon: with the same number of atoms, Impulse MoS2 slabs have more action sites.

Impulse® HR 1226

Middle Distillates Ultra Deep Hydrodesulfurization

Impulse® HR 1226 brings very high hydrodesulfurization activity for diesel and kerosene fractions.

Impulse® HR 1246

Middle Distillates Ultra Deep Hydrodesulfurization

For the most difficult hydrodesulfurization of diesel and kerosene fractions, Impulse® HR 1246 is the catalyst of choice.

Impulse® HR 1256

Middle Distillates Ultra Deep Hydrodesulfurization

Impulse® HR 1256 is a boosted CoMo catalyst allowing to operate difficult cocktail of feedstocks blends in the HDS unit.

Impulse® HR 1218

Middle Distillates Ultra Deep Hydrodesulfurization

Impulse® HR 1218 presents very high denitrification and aromatic hydrogenation activities, as well as a superior desulfurization activity as compared with previous generation catalysts.

Impulse® HR 1248

Middle Distillates Ultra Deep Hydrodesulfurization

Impulse® HR 1248 is the most active NiMo type catalyst. It offers very high denitrification and maximum aromatic hydrogenation activity, as well as a superior desulfurization activity as compared with previous generation catalysts.

HR 626

Distillates Ultra Deep Hydrodesulfurization.

HR 626 is a high surface area, stabilized CoMo catalyst with a highly dispersed active phase. This combination of characteristics, along with its controled pore structure tuned for ULSD service, ensures a highly efficient use of the active metal phase, with a maximized amount of Advanced Catalytic Engineering (ACE®) active sites.

HR 608

Petroleum cuts Deep Hydrorefining.

HR 608 presents very high denitrification and aromatic hydrogenation activities, as well as a superior desulfurization activity as compared with previous generation catalysts.

HR 648

Diesel cuts Deep Hydrorefining.

HR 648 has been designed and optimized for the most severe hydrotreatment service encountered when processing middle distillate cuts containing large amounts of cracked materials under medium to high pressure conditions.

HR 638

Upcycled Catalysts for Naphtha Hydrotreatment Applications

HR 638 was developed to address the new challenges in modern naphtha hydrotreatment. It can be used to pre-treat a wide range of feedstocks, from straightrun naphtha to visbreaker or cracked naphtha (up to 100%)

HR 618

Naphtha Fractions Ultra Deep Hydrodesulfurization.

HR 618 is a recently-developed NiMo type catalyst, used for the hydrodesulfurization and hydrotreatment of naphtha fractions. In addition to a high hydrodesulfurization activity, HR 618 optimized carrier texture and formulation also provides to the catalyst an exceptional stability.

HR 955

Naphta Hydrotreatment of cuts containing Olefins.

HR 955 is a NiMo type catalyst to be used in front of hydrotreatment catalysts for Diolefins saturation. HR 955 special design limits the polymerization of olefins and diolefins and thus, the gums formation, even at low hydrogen partial pressure. The resulting advantage is longer cycle of operation.

HR 608

Petroleum cuts Deep Hydrorefining.

HR 608 presents very high denitrification and aromatic hydrogenation activities, as well as a superior desulfurization activity as compared with previous generation catalysts.

HR 648

Diesel cuts Deep Hydrorefining.

HR 648 has been designed and optimized for the most severe hydrotreatment service encountered when processing middle distillate cuts containing large amounts of cracked materials under medium to high pressure conditions.

Of Impulse® Catalysts with Revival®

After regeneration by coke burning, Impulse® Catalysts can be used again directly, however they will suffer from a deficit of activity as compared with a fresh batch of catalysts.

Revival® is an Axens proprietary process of chemical and thermal treatment allowing regenerated Hydroprocessing and Hydrocracking catalysts to recover their original activity. Thanks to a second stage treatment, it allows regenerated Impulse® Catalysts to come back to their original activity.

Key advantages:

- Activity recovery above 90% as compared with fresh catalysts

- No impact on the mechanical properties of the catalysts

- Catalysts handling and activation procedures are similar to fresh catalysts

Depending on the history of the used catalyst, Axens experts, through Revival® offer, guarantee customer performance targets by conducting engineering studies and surveys to maximize the catalysts reuse.

Resources

You Might Be Interested In

Speciality Bed Topping

Gums & Polymer formation control

Silica Management

TO CONTACT US

Please fill in the contact form below