First published in PTQ Q3 2017

Jacinthe Frecon, Technology Group Manager

DAO Quality

The quality of DAO is primarily a function of the vacuum residue properties, SDA solvent, and SDA operation. Heavier, more aromatic crudes tend to contain more sulphur, nitrogen, CCR, metals, and asphaltenes; consequently, DAO produced from these crudes will comparably contain more heteroatoms than lighter crudes.

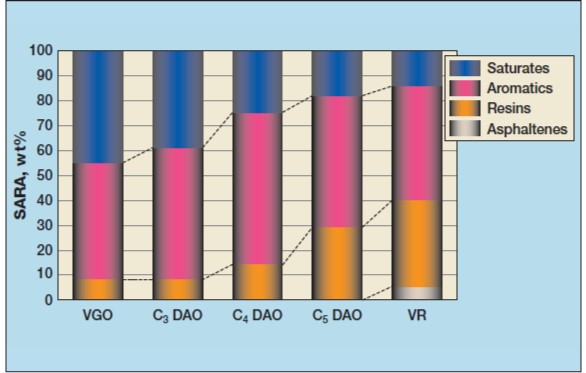

The composition of vacuum residue can be described in four distinct fractions: saturates, aromatics, resins, and asphaltenes. Assuming proper design and operation of the SDA unit, the asphaltene fraction should be mostly rejected with the pitch in the extractor regardless of the solvent composition (down to the ppm range), and the saturates will be mainly extracted with the DAO. This leaves the aromatics and resins as the fractions most affected by the type of solvent and operation of the SDA unit. Heavier solvents achieve higher DAO lift by extracting more of the aromatic and resin phase while lighter solvents extract mainly saturates while rejecting much of the aromatic and resin molecules with the pitch. Figure on the left summarises this relationship for an Arabian Light residue.

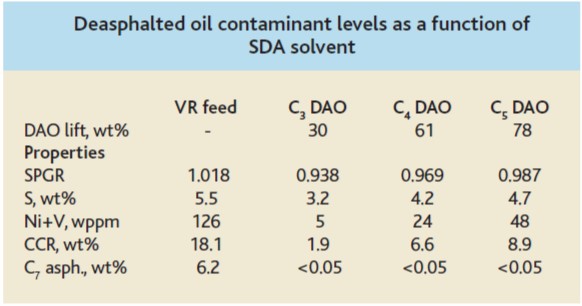

Table below summarises DAO contaminants as a function of SDA solvent for a fixed crude VR.

DAO hydrocracking catalytic solutions

Looking to the table on the left, the first challenge is to cope with higher level of contaminants (metals, asphaltenes, CCR) and inhibitors (polyaromatics, nitrogen-containing organic molecules) compared to VGO feed which are usually processed.

In order to answer that challenge, the solution is to combine specific grading with scale traps, metals traps and stack bed catalyst loading, enabling a gradient of hydrotreating activity. For instance, after demet catalyst, metal tolerant hydrotreating catalyst with medium activity is loaded before going to pure hydrotreating catalyst.

The second challenge is to perform a deep hydrotreatment of the large molecules (including polyaromatics), to maximise denitrification and aromatic saturation before feeding cracking catalyst.

Indeed, due to the large presence of polyaromatics in DAO cut, hydrotreating and hydrocracking catalysts will need a high hydrogenation function to transform these molecules.

The third challenge is to crack those large molecules. Optimisation of the acid phase in hydrocracking catalysts was implemented for DAO feed to improve diffusion of bulky molecules to the active acid site of the zeolite:

- The dispersion of zeolite crystals into the mesoporous binder is optimised, avoiding agglomerates of crystals and thus maximising access of DAO molecules to the zeolite.

- The mesoporosity of the zeolite is also optimised to allow molecules to access active sites via mesoporosity to microporosity where acid sites are mainly located. The mesoporosity is also well connected to the external surface to favour desorption of cracked products.

Get the latest news about Proven Solutions in Oil Refining

Subscribe to our business newsletter to keep up to date with Axens news.

This newsletter gives access to our experts' insights and the opportunity to stay up-to-date with our latest products, technologies and services.