First published in PTQ Q4 2021

Romain Roux, Advisor to CTO New Market Development, Axens

Starting with SMR in the refinery, you will have three steps for decarbonisation:

- Carbon capture on the SMR synthetic gas itself: Amines can provide a reduction in the SMR unit’s CO2 emissions by more than 50%. Axens is proposing its AdvAmine™ technology. With more than 200 references, AdvAmine™ has recently been applied to green hydrogen production on syngas as well, but from Biogenic feedstock.

- Retrofitting the existing SMR in order to reduce CO2 emissions: A simple revamping of the furnaces will typically provide a reduction of more than 10% of the SMR unit’s carbon intensity.

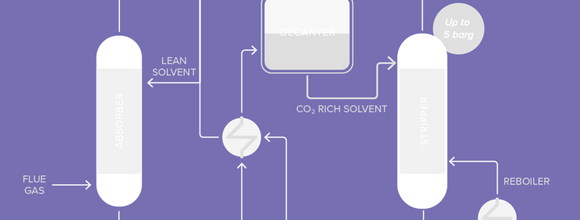

- Carbon capture on the flue gas: Axens is currently developing a dedicated solvent based carbon capture technology – DMX™ – aimed at capturing CO2 at low pressures in industrial flue gases with low CO2 content. DMX™ will be fully demonstrated in 2022 on a steel manufacturing site. Axens is already proposing studies in order to evaluate the impact of DMX™ installations on decarbonisation projects.

The alternative would be to buy hydrogen (green or blue) to reduce CO2 emissions, or to develop an in-house green hydrogen project.

Blue hydrogen in general is sensitive to the effect of scale. Therefore, blue hydrogen will be economical only if the SMR unit is large, not too far from the site of consumption and when CO2 exports or valorisation are economical.

For green hydrogen, or more specifically hydrogen from electrolysis, many refineries are developing moderate-scale (tens of MW) electrolyser projects at their sites, but many projects are also based on production by a third party selling hydrogen. As this is a new market, the preferred business model as to whether to produce or buy green hydrogen has not yet been defined.

Axens Offer in CO₂ Capture: DMX™ and AdvAmine™

Technical Article - The role of integrated and derisked technologies as a cornerstone of eFuels deployment

Webinar - Axens Post Combustion Carbon Capture with DMX™ Technology

Technical Article - DMX CO2 capture technology, an industrial demonstration

Carbon Capture: an Introduction to the Mature and Emerging Technologies

Carbon Capture: an Introduction to the Mature and Emerging Technologies

What is the Current Status of CCS Facilities Around the World?

How the Different Energy Policy Choices and Technological Solutions Affect GreenHouse Gas Emissions Reduction?

What Are the Main Sectors Emitting CO2?

White Paper - Carbon Capture & Storage

Successful demonstration in Dunkirk of the CO₂ capture DMX™ process

DORIS, Axens, AWT International, SeaQuester and Surbana Jurong announce the CCS Hub Alliance decarbonisation solution for hard-to-abate CO2 emitters

DORIS and Axens signed a MOU for Carbon Capture, Utilization and Storage services

Técnicas Reunidas and Axens Sign an Agreement to Develop Carbon Capture and Storage Projects

Webinar - Axens Post Combustion Carbon Capture with DMX™ Technology

Read more

Video - 3D Project: a European Project for CCS on an Industrial Scale

Read more