Axens Offer

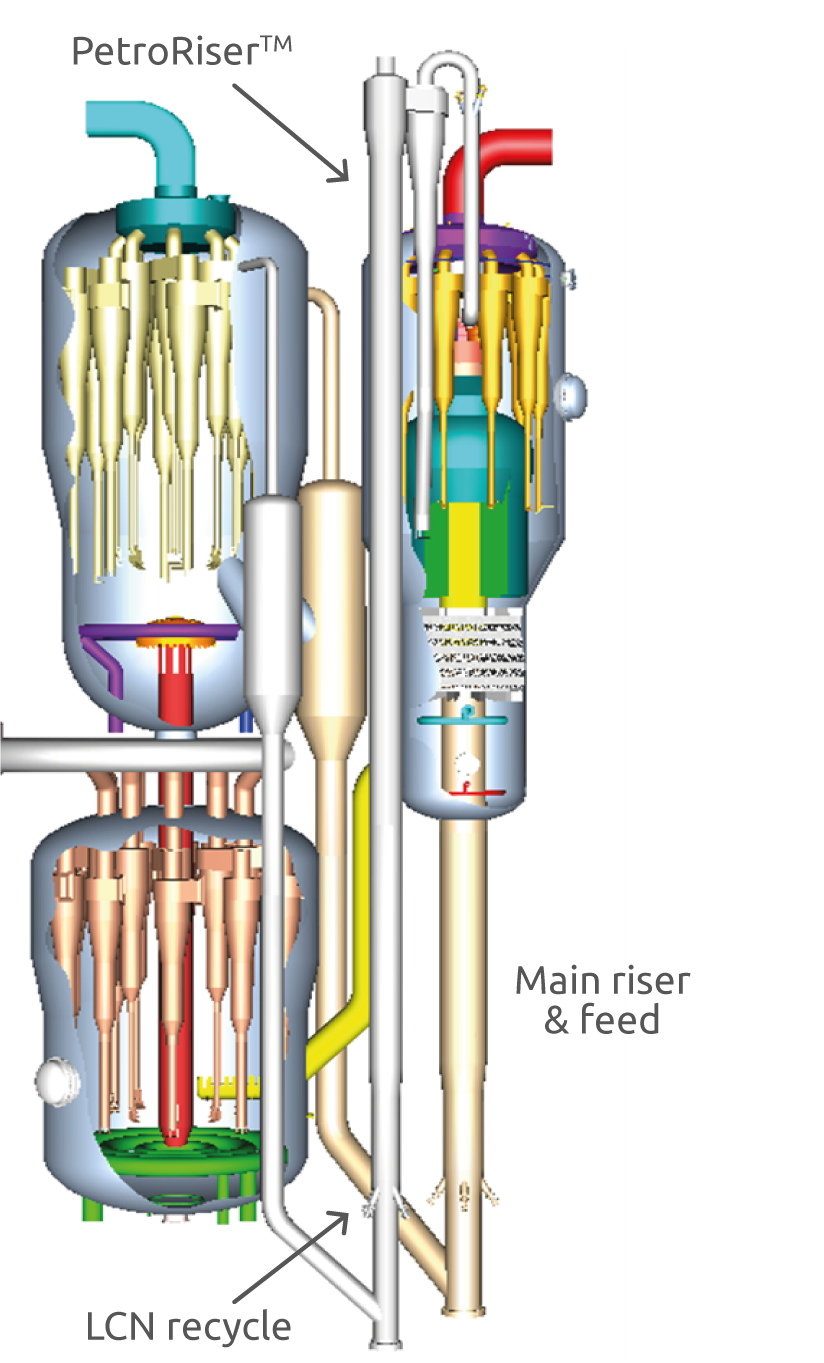

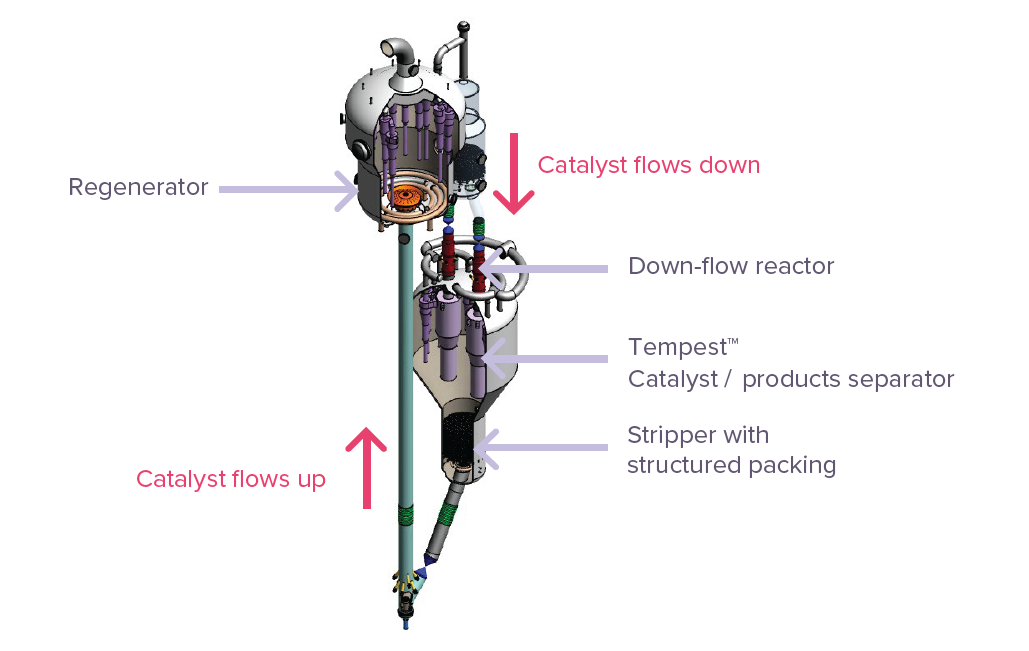

Axens offers state-of-the-art FCC technology for traditional gas oil cracking and residue cracking. This advanced technology has been brought to market through the efforts of a partnership between Axens (technology developer and licensor), IFP Energies nouvelles (R&D), Total (operations expertise) and TechnipFMC (engineering innovation).

These units have achieved more than 200 years of proven commercial operation in processing over 2 million BPD of feedstocks ranging from gas oils to heavy residues.

When processing traditional distillate feeds or blends with a Conradson Carbon Residue (ConC or CCR) content less than around 2 to 3 wt. %, a single stage regeneration system operating in complete or partial combustion mode is generally adequate.

When processing residues containing high levels of metals (Ni, V and Na) and ConC values in excess of 3 wt.%, more sophisticated FCC designs are required.

The Petrochemical industry requires ever more propylene to supply the expanding chemicals and polymers markets.

In order to address the general lack of propylene from steam crackers, dedicated propylene production technologies, Axens has developed a large portfolio of solutions to produce more propylene per barrel of crude oil: High Propylene FCC (HP FCC™), Resid to Propylene (R2P™), FlexEne™, HS-FCC™ (High Severity FCC) and Olicrack™.

Resources

Technical Article - Guiding the crude-to-chemicals complex towards a net-zero future

Maximizing the Production and the Transformation of Aromatics

Targeting the Highly Coveted Olefins

Two Conversion Routes to Maximize the Economic Returns of a Crude-to-Chemicals Project

Maximizing the Production and the Transformation of Aromatics

Targeting the Highly Coveted Olefins

Two Conversion Routes to Maximize the Economic Returns of a Crude-to-Chemicals Project

Recommended Process Routes for Maximized Oil Conversion to Aromatics and Olefins

White Paper - Crude-to-Chemicals

Technical Article - Guiding the crude-to-chemicals complex towards a net-zero future

Technical Article - Maximize Refinery Profitability with Novel RFCC Technologies

Technical Article - Technology Advances Enable Crude To Chemicals Projects

Technical Article - Shale Gas Drives New Opportunities For US Downstream

SOCAR's Heydar Aliyev Oil Refinery Signs License And Design Agreements With Axens For The Fluid Catalytic Cracking Unit

Axens’ Technologies for HPCL Rajasthan Refinery in India

Saudi Aramco, TechnipFMC and Axens advance Catalytic Crude to Chemicals technology

Pertamina Licenses Axens Technologies for its Balikpapan and Cilacap Refineries in Indonesia

TO CONTACT US

Please fill in the contact form below