MEG Recovery

Natural gas production leads more and more to the development of deep offshore gas projects under stringent conditions, with the associated risks of hydrate formation, leading to blocked flowlines and potential plant shutdowns.

Different solutions exist to avoid hydrate formation:

• MonoEthylene Glycol (MEG) injection

• Methanol (MeOH) injection

• Low Dosage Hydrate Inhibitor (LDHI) injection

• Heating and insulation of the flowlines

Axens Offer

Injection of MonoEthylene Glycol (MEG) at the wellhead is a widely spread solution for hydrate inhibition and guarantees continuous gas production.

The installation of a MEG regeneration and reclamation system is crucial to recover MEG suitable for re-use.

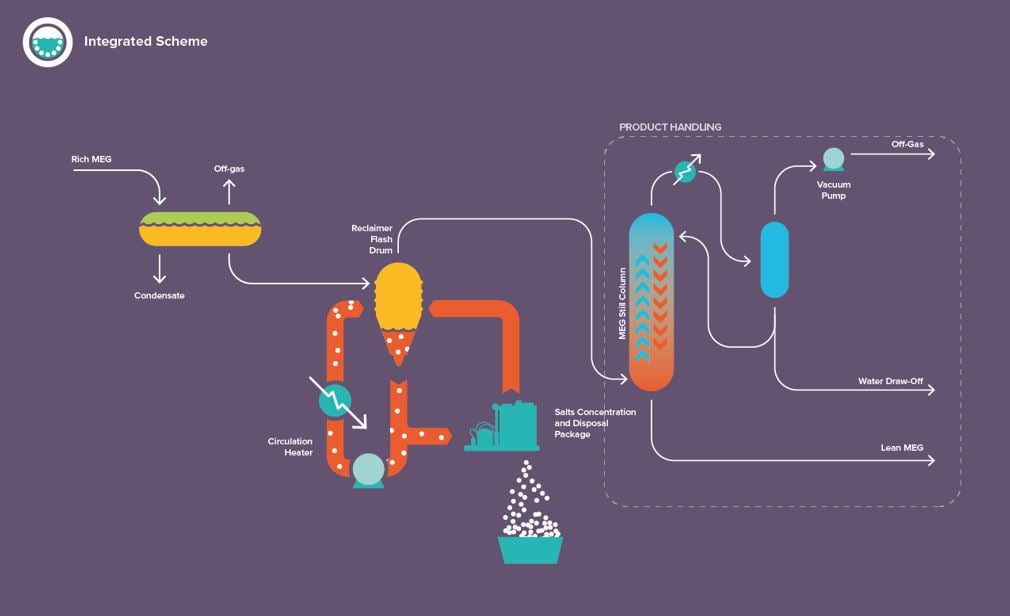

AdvaMEG®, Axens MEG Regeneration and Reclamation solution, proposes the most reliable response for this purpose. It uses a vacuum distillation and purification system protected by several patents, allowing the removal of water from the rich MEG but also all types of salts (monovalent & divalent salts) coming from reservoir and subsea system. The technology removes contaminants and enables high MEG recovery while minimizing waste effluents.

For each project, AdvaMEG® offers a tailor-made solution with high flexibility, optimizing scheme with specific features adapted to each feedstock. Thanks to its deep experience and knowledge in the field of MEG reclamation, Axens is able to advise on the most relevant scheme depending on project constraints such as compact modular units when space is limited, staged investment approach to reduce initial CAPEX and CO2 emission reduction.

For Each Constraint, an Adapted Scheme

Thanks to the integrated scheme, water and salts are removed in the same unit operating under vaccum to produce a salt free lean MEG. Both monovalent and divalent salts are removed from the MEG without any additional divalent removal unit.

Conditioning

Contaminants removal from the entering rich MEG:

- Hydrocarbons

- Acid gases

- Corrosion products

-...

Reclamation

Vaporization of both MEG and water under vacuum to produce a concentrated slurry of salts.

Salts Removal

Monovalent and divalent salts removal from the concentrated slurry of salts using vertical basket type centrifuge to achieve high solids cake dryness with low MEG losses.

Overhead Regeneration

Water and MEG separation under vacuum to produce lean MEG at the required concentration and water with low MEG content.

This type of scheme is well adapted when no salts are present in the feedstock, for example during early life of a reservoir.

If a limited quantity of salts is expected, Axens can propose salt-robust regeneration design to handle them even if they are not removed.

Conditioning

Contaminants removal from the entering rich MEG:

- Hydrocarbons

- Acid gases

- Corrosion products

-...

Regeneration

Water and MEG separation slightly under pressure to produce a salty lean MEG at the required concentration and water with low MEG content.

For moderate salt content and large rich MEG capacity applications a slip-stream configuration can be proposed.

This scheme allows a partial removal of salts to produce a salty lean MEG, typically at 2% wt of salts.

It is also well adapted to a staged investment approach or for retrofit of conventional regeneration (pretreatment and reclamation sections are added when salts production starts).

Conditioning

Contaminants removal from the entering rich MEG :

- Hydrocarbons

- Acid gases

- Corrosion products

-...

Chemical Pretreatment

Dedicated section designed to precipitate the divalent salts thanks to chemical injection. Then they are concentrated as a salt cake while minimizing the MEG losses.

Regeneration

Water and MEG separation slightly under pressure to produce a salty lean MEG at the required concentration and water with low MEG content.

Reclamation

MEG vaporization under vacuum to produce a concentrated slurry of salts.

Salts Removal

Monovalent salts removal using vertical basket type centrifuge to achieve high solids cake dryness with low MEG losses.

Events

All eventsContact Us

Please fill in the form below to get in touch with us