Axens’ large technology portfolio includes all the processing steps to produce Group III lube base oils from Vacuum Gasoil (VGO) or Deasphalted Oil (DAO) feedstocks. For this purpose, a combination of hydrocracking (HyK™) and hydrodewaxing (HyDeWax™) technologies is the best choice.

Besides base lube oil technologies, Axens also offers wax hydrotreatment, white oils hydrotreatment technologies allowing our customer to produce different special oils including:

- Feed-grade wax

- Technical grade white oils

- Medical white oils

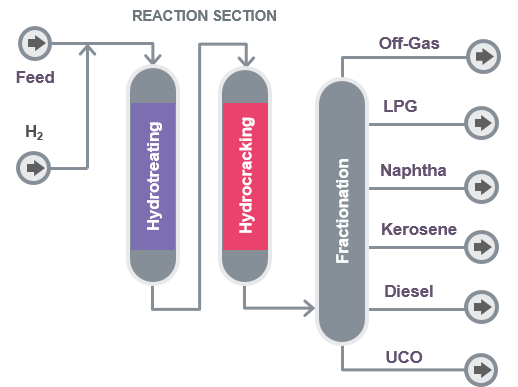

The target of Axens Solutions' Hydrorefining technology is the production of a wide choice of suitable lubricant base stocks from a variety of crude sources. Very similar to the hydrocracking process regarding operating conditions, it uses a special amorphous catalyst having a dual function (hydrotreating and cracking).

The production of lube oils with Viscosity Index (VI) values between 95 and 145 is associated with a conversion to lighter fractions between 20 and 60 wt%.

Axens Solutions' HyDeWax™ technology allows the production of high-quality Group III Lube base oils from Unconverted Oil (UCO) from Hydrocracker or from Hydrorefined Vacuum Gasoil (VGO)/Deasphalted Oil (DAO) feedstocks or from 100% Wax feed. The latest combination of hydro-isomerisation and hydrofinishing catalysts will ensure excellent yields and optimum lube quality and stability.

In order to produce white oils from the existing base oils of the refinery, it is necessary to completely hydrogenate aromatic structures into naphthenic ones.

Waxes coming from Deoiling need a final hydrotreatment to be used in food applications.

TO CONTACT US

Please fill in the contact form below