Desalter units references

Proven Technology with rbobust design

salt removal performance for optimized operations

Axens provides global turnkey solutions for Oil and Gas condensate treatment, supplying tailor made Desalter equipment.

Axens combines desalting know-how with its Leading Expertise in Refining technology which provides to Axens’ Desalter a unique positioning in the Market.

Axens is in charge of the design, procurement, manufacturing, testing and delivery of the equipment, as well as spare parts, site services (from commissioning to start-up), training sessions.

Axens brings a continuous support during the lifetime of the equipment to support its customers (revamping, troubleshooting, operation optimization...)

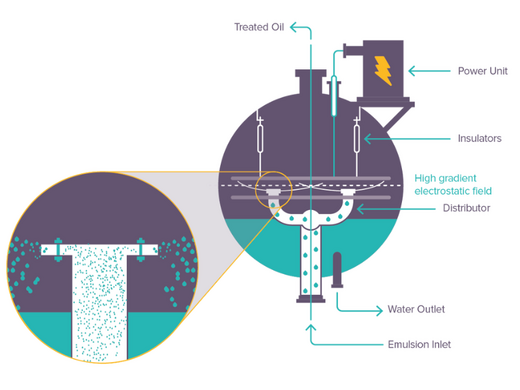

Desalting combines 3 steps to achieve Salts removal: Injection of fresh clean water to wash crude oil, coalescence to promote droplet growth and separation by gravity.

Electrostatic desalters is the most versatile and effective technology. The electric field enhances water droplet coalescence, reducing residence time between the grids as well as the use of chemicals (demulsifer).

TO CONTACT US

Please fill in the contact form below